Pyramid Type Plate Bending Machines Are The Most Popular Plate Bending Machines Working In India

With Over A Hundred Machines In Use.

They Are Designed For Production Of Cylindrical Shells Used For Pipes, Storage Tanks, Chimneys,

Pressure Vessels, Etc.

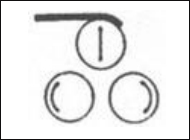

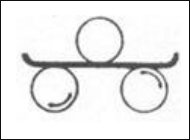

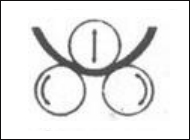

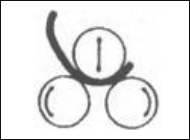

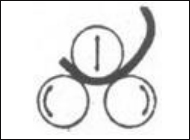

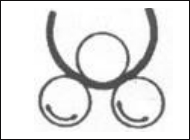

These Heavy Duty Plate Bending Machines Employ the Three Roller Pyramid Principle.

Bottom Rolls Are Fixed and Are Driven By a System of Gears and Worm Reduction Gear Box

Whereas The Top Roll Has a Vertical Up And Down Movement through Screws Adjusted Manually

Combining modern technologies with innovative product development concepts.

We Astha Infra Engg (India) Pvt.Ltd, have been considered to be a leading manufacturer

of the Plate Bending Machine. We own expertise and rich industrial experience in engineering

that reflects in our innovative range of Plate Bending Machines.

We are an eminent plate bending manufacturing company, engaged in offering standard and

custom-made bending machines which are simple in operation, highly effective, secure,

convenient and fast.

Our company that is firmly committed to maintaining quality standards. Therefore, we rely

on our excellent quality controlling mechanism to assure the best-in-quality assortment of

plate bending machine at competitive prices, hence holding out maximum client satisfaction.